- Monday 8:00 AM - 5:00 PM

- Tuesday 8:00 AM - 5:00 PM

- Wednesday 8:00 AM - 5:00 PM

- Thursday 8:00 AM - 5:00 PM

- Friday 8:00 AM - 5:00 PM

- Saturday 8:00 AM - 12:00 PM

- Sunday Closed

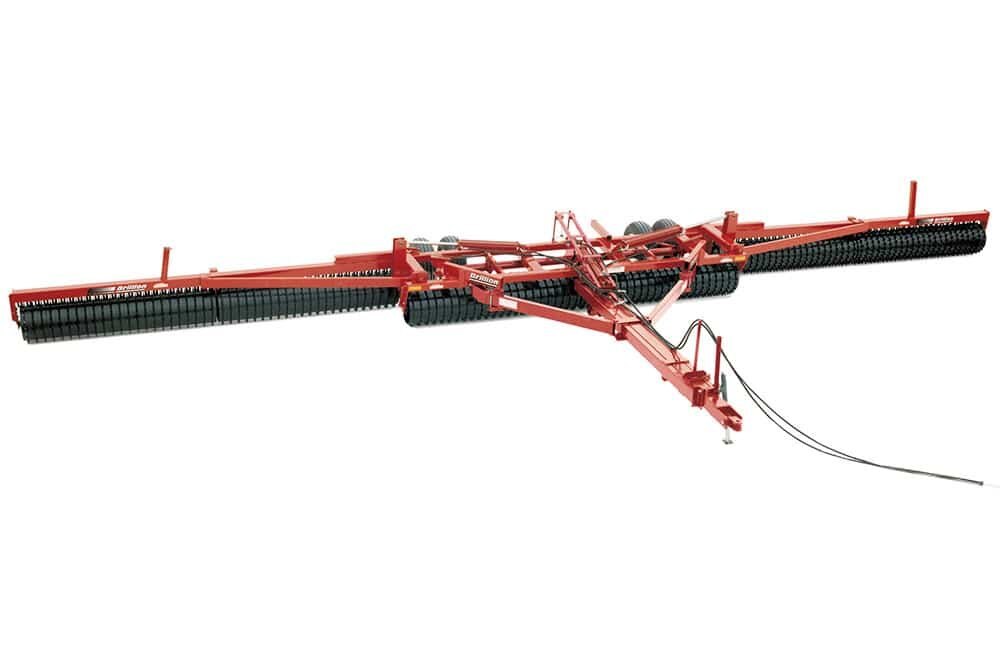

Brillion Pulverizer

-

ID # 33459339

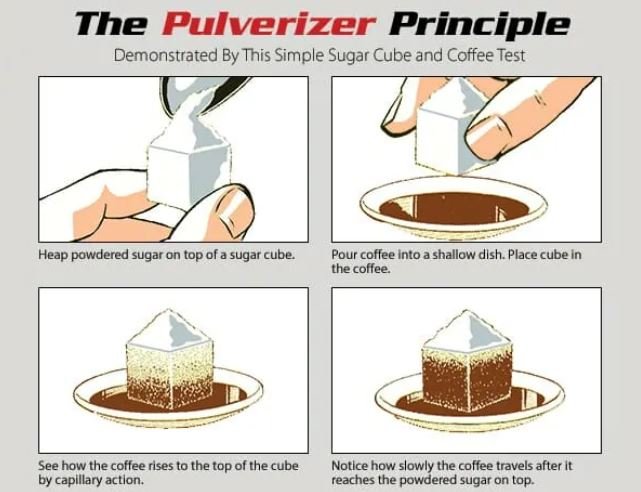

It’s About Higher YieldAll models in the Brillion Pulverizer line have a common denominator…HIGHER YIELD. Producers know that higher yields start with a properly prepared seedbed and a firm seedbed is critical to maintain a uniform planting depth. The ideal seedbed should be firm with fine particles at the seed depth and should have a layer of loose mulch on the surface to slow evaporation and conserve moisture. Many of the most valuable nutrients are locked in the clods and root crowns left in the field. The Pulverizer crushes those clods and breaks down the root crowns to release those nutrients for use by the crop. At the same time, air pockets are eliminated and moisture is drawn into the root zone through capillary action. Good seed to soil contact creates more uniform germination, pollination, and maturity…and that means increased yields and greater profits. |

It’s About the SoilThe Brillion Pulverizer line is a genuine asset to the value of the soil and can be the missing link in improving the soil from mediocre to a good growth environment with just a single pass. The ribs or ridges on the Pulverizer wheels/rolls are the real workhorses; the residue is anchored into the surface of the seedbed so it can’t be blown or washed into road ditches, waterways, culverts, etc. The ribs form a distinct texture on the surface that allows the soil surface to breathe in the event of a crusting rain. The soil will normally split and crack along the rib cuts to allow oxygen and water to enter the soil and to give small seeds a place to grow through. Some producers also utilize the Pulverizer (equipped with notched wheels) in a post-plant mode, further firming the seedbed for optimum germination. |

It’s About SmoothThe Brillion Pulverizer will put a smooth, textured finish on the seedbed. The smooth seedbed allows for closer to the surface harvest in a soybean field and the ultimate opportunity for high-speed cutting and harvesting of alfalfa. The smooth seedbed also has any small to medium-sized stones pushed into the soil to lessen the occurrence of an ingestion by a combine or forage harvester. |

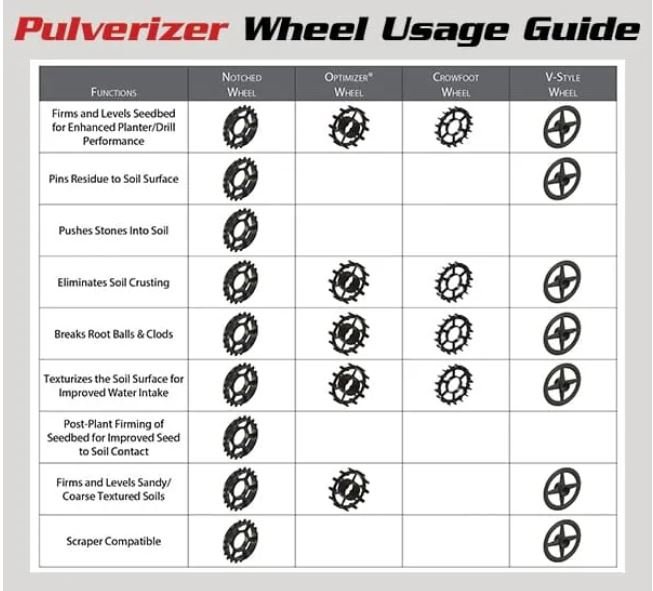

Endless Models and Wheel OptionsBrillion offers Pulverizer models in sizes from 5’ up to 52’. There are three-point hitch models, rigid transport pull-type models, and folding pull-type units available. Each series has its own unique features and choice of Pulverizer wheel options. |

Endless Options and Sizes to Accommodate Any Operation

|

WFP Series, Wing Float Pulverizer – 23′ to 37′ Models

|

WFP Series, Wing Float Pulverizer – 38′ to 52′ Models

|

X Series, Folding Pulverizer – 20′ to 26′ Models

|

XL Series, Folding Pulverizer – 28′ to 36′ Models

|

XXL Series, Folding Pulverizer – 38′ to 46′ Models

|

PT Series, Rotating Frame Transport Models

|

P Series, Pull-Type/No Transport Models

|

PP Series, Three-Point Hitch Models

|

PFT Series, Floating Ring Models

|

SD Series, Double Gang Models

|

| Name | Link |

| WFP Series, Wing Float Pulverizer, 23 ft. to 37 ft. Models PDF Specs | Download |

| WFP Series, Wing Float Pulverizer, 23 ft. to 37 ft. Models Excel Specs | Download |

| WFP Series, Wing Float Pulverizer – 38 ft. to 46 ft., 50 ft. 52 ft. Models PDF Specs | Download |

| WFP Series, Wing Float Pulverizer – 38 ft. to 46 ft., 50 ft. 52 ft. Models Excel Specs | Download |

| X Series, Folding Pulverizer – 20 ft. to 26 ft. Models PDF Specs | Download |

| X Series, Folding Pulverizer – 20 ft. to 26 ft. Models Excel Specs | Download |

| XL Series, Folding Pulverizer – 28 ft. to 36 ft. Models PDF Specs | Download |

| XL Series, Folding Pulverizer – 28 ft. to 36 ft. Models Excel Specs | Download |

| XXL Series, Folding Pulverizer – 38 ft. to 46 ft. Models PDF Specs | Download |

| XXL Series, Folding Pulverizer – 38 ft. to 46 ft. Models Excel Specs | Download |

| Name | Link |

| PPF Series (6′ to 18′ 3-Point Hitch Models) Operator’s & Repair Parts Manual | Download |

| PFT Series – (20′ to 22′ Pull-Type Models) Repair Parts Manual | Download |

| PFT Series – (20′ to 22′ Pull-Type Models) Operator’s Manual | Download |

| PFT Series – (10′ to 18′ Pull-Type Models) Repair Parts Manual | Download |

| PFT Series – (10′ to 18′ Pull-Type Models) Operator’s Manual | Download |