- Monday 8:00 AM - 5:00 PM

- Tuesday 8:00 AM - 5:00 PM

- Wednesday 8:00 AM - 5:00 PM

- Thursday 8:00 AM - 5:00 PM

- Friday 8:00 AM - 5:00 PM

- Saturday 8:00 AM - 12:00 PM

- Sunday Closed

Rental Equipment

At Bob Mark Equipment Sales & Rentals

SNOW REMOVAL RENTALS ARE AVAILABLE NOW FOR THE WINTER 2025 SEASON.

BOOK YOURS NOW

Go ahead and start your next job knowing you have equipment for as long as you need it. Whether you’re working on a short-term project or need a replacement while your equipment is in for repair, we have rentals to support you.

There’s no need to finance long-term or make payments year-round on something you’ll only use for a day, week, or season.

So, rent farm and construction equipment at Bob Mark in Lindsay, Sunderland, Napanee, or Campbellford. Delivery available.

Commonly available units include:

- HLA snow plows and pushers installed on CTLs and wheel loaders

- Hyundai wheel loaders, dozers, and excavators

- New Holland excavators, compact wheel loaders, mini track loaders, tractors, compact track loaders, backhoes, and skip loaders

- Vaderstad discs

- Seeders

- Dump trucks

See below for all available inventory.

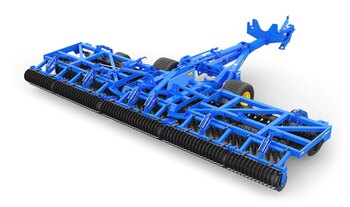

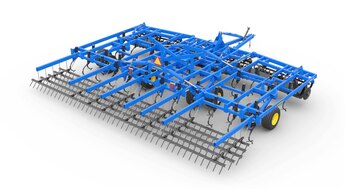

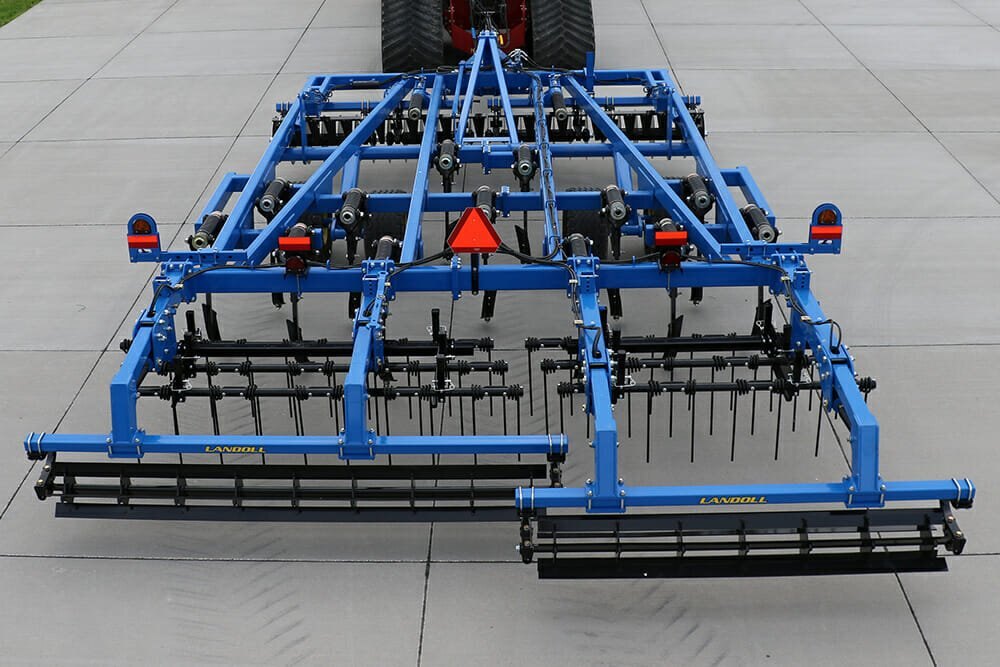

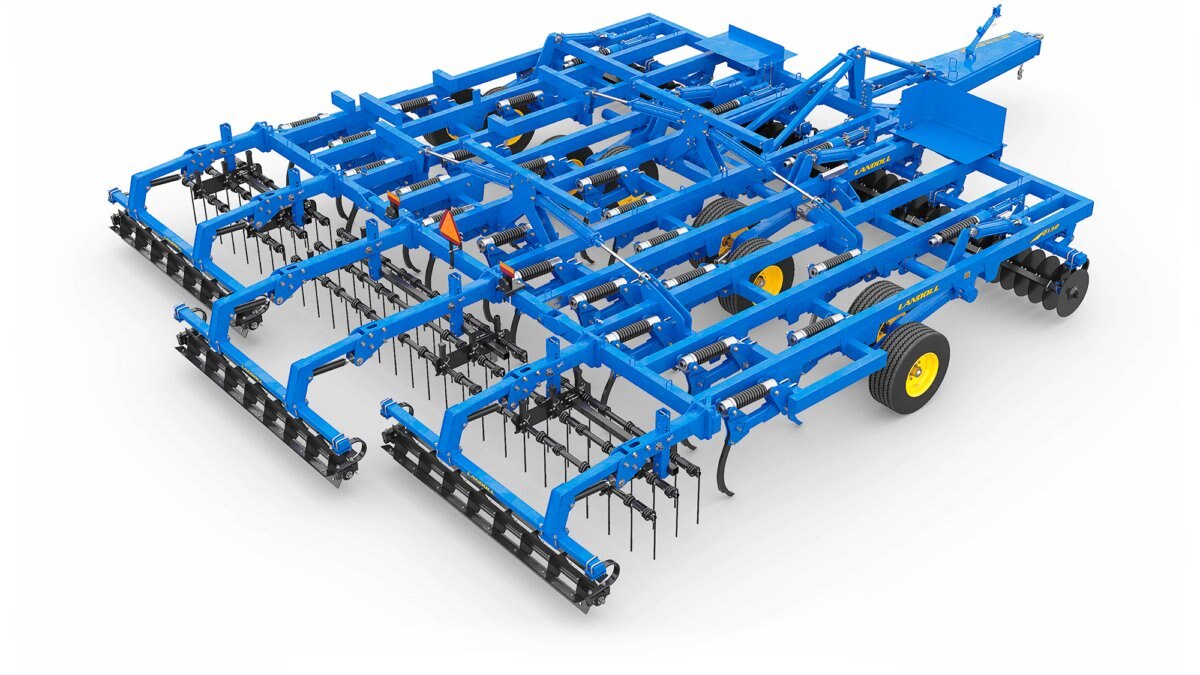

Landoll 2100 SERIES COULTER CHISEL

UPDATED DESIGN BUT PROVEN CONCEPT

UPDATED DESIGN BUT PROVEN CONCEPT

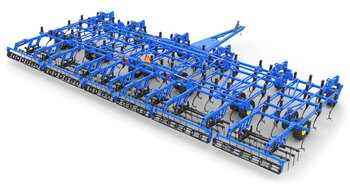

The coulter chisel concept has been used for decades as an alternative primary tillage practice. The newly redesigned Landoll 2100 Series Coulter Chisel incorporates this concept into high capacity. This translates to handling heavy residue at higher speeds with maximum efficiency. Cover more acres per hour using less horsepower per foot than conventional disc rippers. |

SIZE HEAVY RESIDUE AND ELIMINATE COMPACTION

SIZE HEAVY RESIDUE AND ELIMINATE COMPACTION

Available in sizes from 9 to 25 shanks allowing for cutting widths of 11’3” to 31’3”, these models will work with a wide range of tractor sizes and provide ultimate productivity for nearly any operation. Residue is sized every 7 ½” with the front 22” cutting coulters. Compaction is eliminated and residue is blended in with the heavy-duty shanks spaced at 15”. Shanks are mounted on staggered bars allowing residue to easily flow through the machine. In addition, shanks are arranged to follow a coulter and have one in between each for optimum residue sizing. |

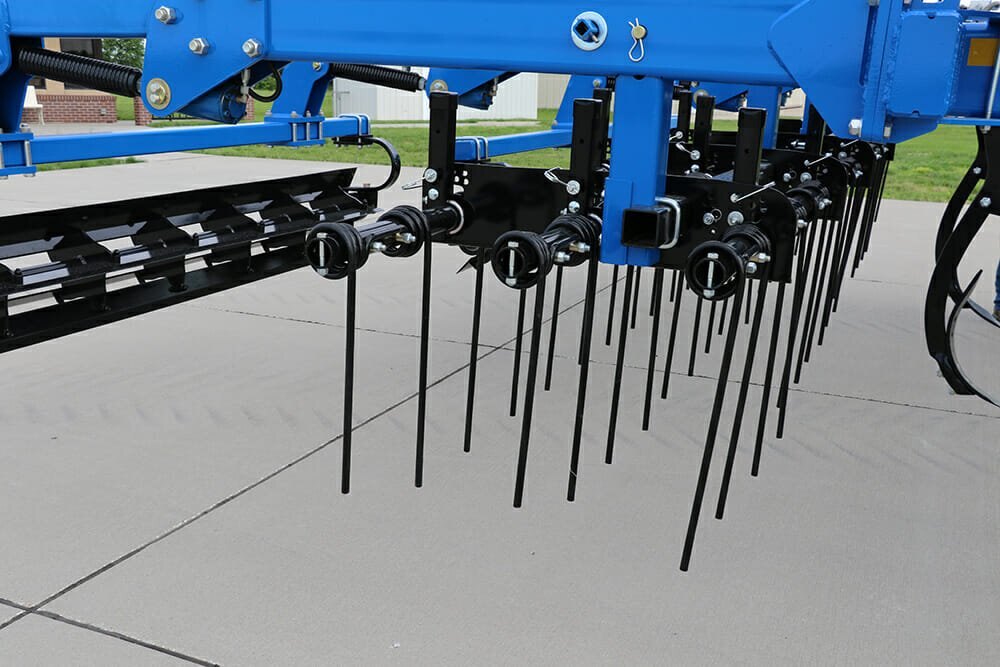

HEAVY-DUTY SHANK ASSEMBLIES

HEAVY-DUTY SHANK ASSEMBLIES

The high-clearance shanks offer 32” of underframe clearance and are available in auto-reset or rigid shear bolt configurations. The auto-reset shank assemblies provide 1,750 pounds of point load, a 14” trip height, and the point angle can be adjusted to 50 or 60 degrees. Twisted shovels or straight points are offered to complete the shank assemblies. |

|

USER FRIENDLY FEATURES

The 2100 Series Coulter Chisel offers single point depth control at the front of the machine. Hydraulically controlled coulters allow for ‘on the go’ adjustments to meet changing conditions right from the comfort of the tractor cab. The self-leveling hitch provides a ‘set it and forget it’ adjustment that maintains level operation from front to rear. The updated design features fewer moving parts to help reduce downtime in the field, and adjustments are simple to make, further increasing efficiency. |

|

LEVELING OPTIONS

The 2100 Series Coulter Chisel can also be outfitted with just the three-row coil tine harrow or just the chopper reels. |

|

REAP BIG BENEFITS

Today’s high yielding crops produce large amounts of heavy residue that must be sized and mixed in the soil to accelerate breakdown. The Landoll Coulter Chisel will perform the ultimate primary tillage pass, setting you up for increased yields the following season. Combine this with Landoll’s state of the art manufacturing processes to have peace of mind that your 2100 Series Coulter Chisel will be in it for the long haul. |

| 22” Coulters on 7 ½” Spacing with Depth Gauge Indicator 1 ¾” Gang Bolt 5 ¾” Solid Cast Spools C-Cushion Bearing Standards with Trunnion Bearings with Triple Lip Seal Scraper Mounted Bracket Attached to C-Cushion Bearing Standard Auto-Reset Shank Assemblies with 1,750 lb. Point Load, 14” Trip Height, 32” Under Frame Clearance, Adjustable 50 or 60 Degree Point Angle Rigid Shear Bolt Shanks with 32” Under Frame Clearance Choice of Twisted Shovels or Straight Points |

| 5 ½” Lift Axles with Maintenance Free Lift System Walking Tandems with Greaseable Bearings on all Sizes 340/65R x 18 Radial Tires with 8-Bolt Hubs and 3” Slip-In Spindles on Rigid Models and Wings of Folding Units 400/60R x 18 Radial Tires with 8-Bolt Hubs and 3 ¼” Slip-In Spindles on Center Sections of Folding Units Self-Leveling Hitch with Manual Adjustment Single Point, Front Mounted Depth Control Blue Powder Coat Paint Adjustment and Gang Wrench |