- Monday 8:00 AM - 5:00 PM

- Tuesday 8:00 AM - 5:00 PM

- Wednesday 8:00 AM - 5:00 PM

- Thursday 8:00 AM - 5:00 PM

- Friday 8:00 AM - 5:00 PM

- Saturday 8:00 AM - 12:00 PM

- Sunday Closed

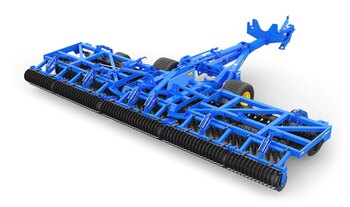

Landoll TILL ‘N SEED

|

|

THE EVOLUTION

THE EVOLUTION

The Till ‘N Seed concept started years ago from customers asking for a ground driven tool to renovate their pastures. Customers were looking for a seeder that would not disturb existing vegetation but would still be able to penetrate the hard surface of the pasture and place the seed at the correct depth for the best chance at germination. Through an extensive design and testing process, the Till ‘N Seed was born. Not only could this seeder renovate pastures as was originally requested, but it was also the perfect tool for repairing damaged alfalfa fields, restoring athletic fields and lawns, de-thatching lawns, and planting and shredding food plots. |

|

|

|

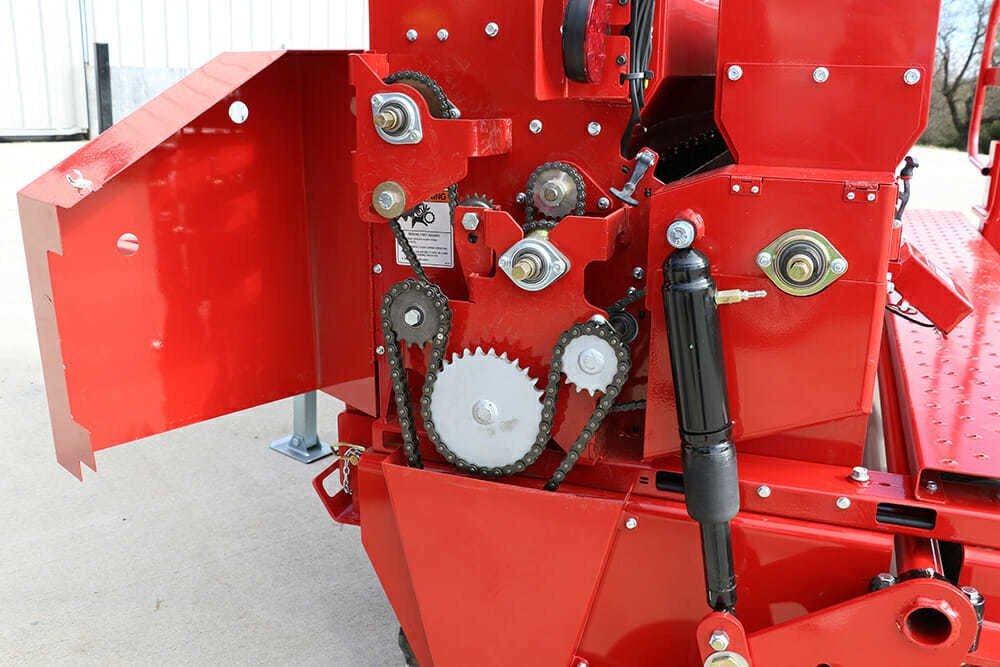

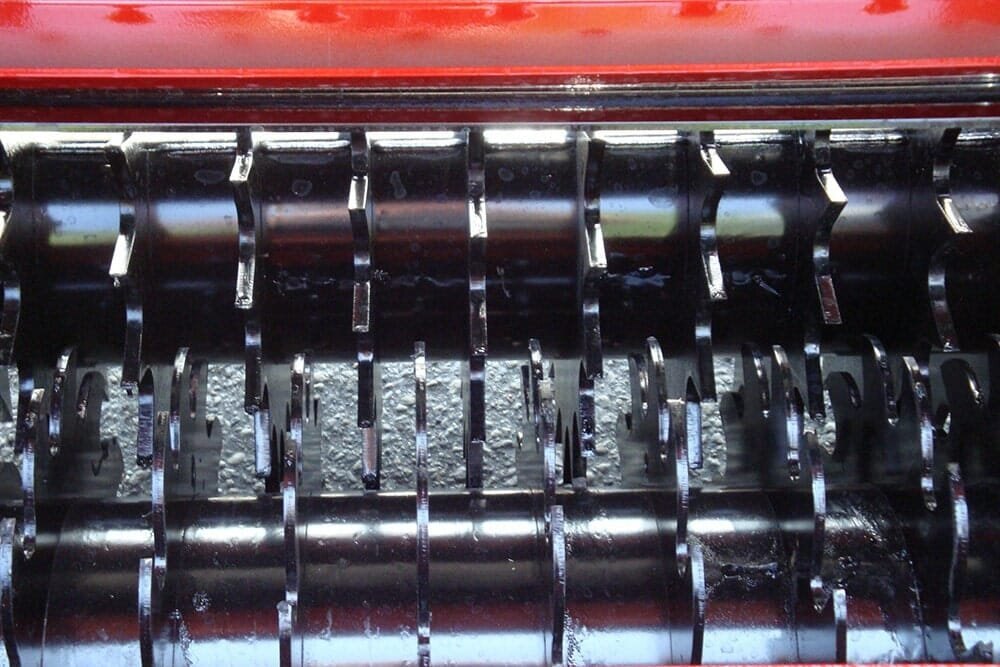

THE WORKINGS

The foundation of the Till ‘N Seed is the one-piece all-welded steel frame, which supports the ground engaging seeding mechanism (rotors) and the seed boxes. To adapt to varying conditions, down pressure on the tillage rotor is adjustable with an air shock and seed depth is set with adjustable gauge wheels. Seeding rates can be fine-tuned for each seed box. The seed is broadcast into the soil as it is opened by the rotors. A rear firming roller finishes the seeding operation by firming the seedbed. |

|

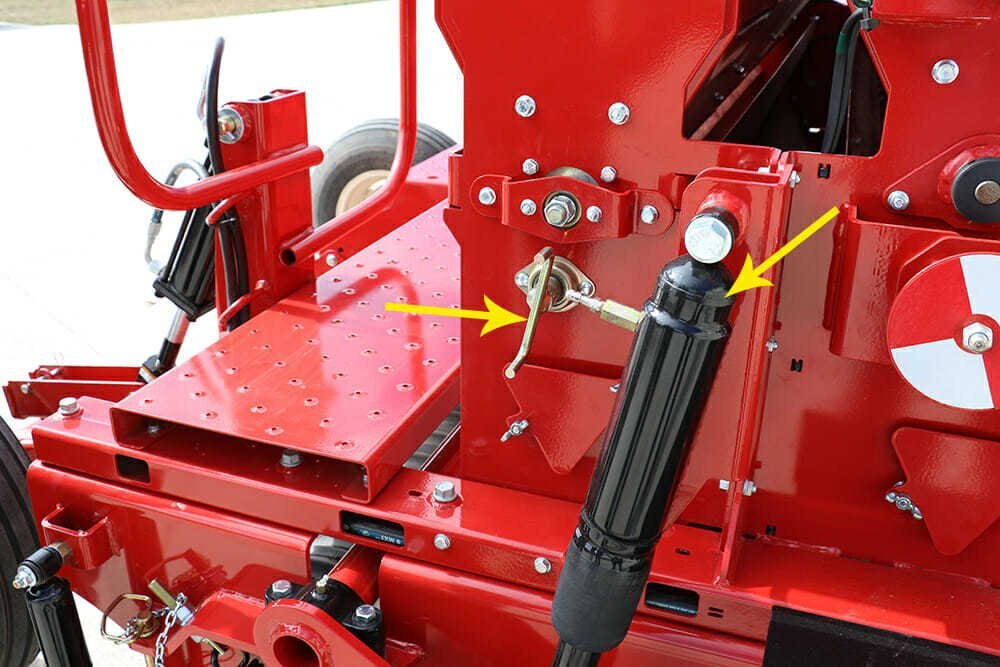

BUILT-IN EXTRAS

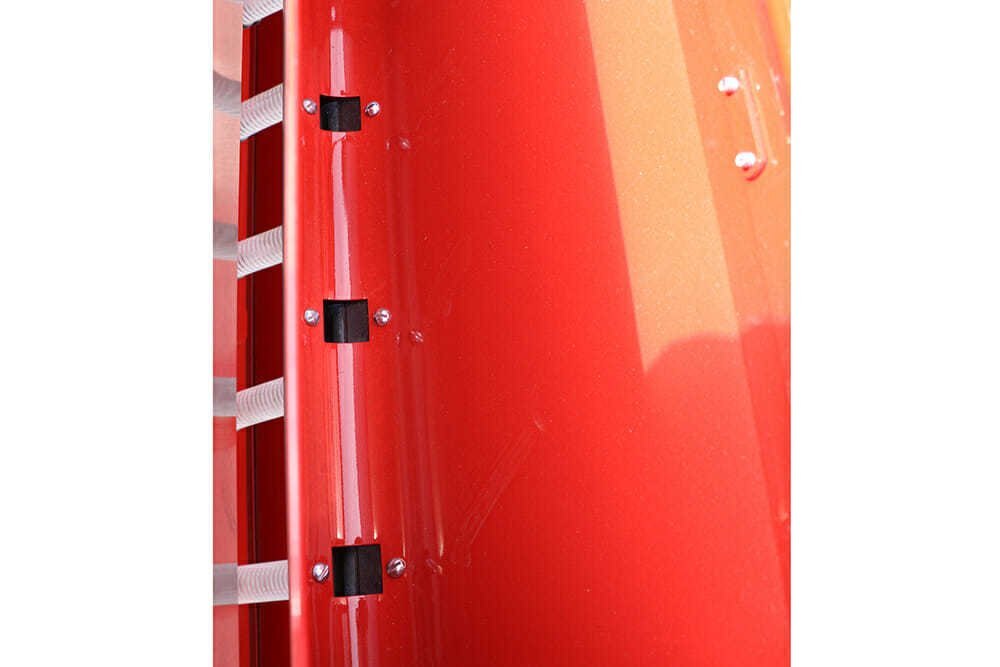

Built-in parking stands allow three-point hitch models to be safely detached from the tractor without the fear of tipping. A built-in walk-board with steps and handrails on the rear of the unit allows for easy filling of the seed boxes. Built-in tie down lugs are included for securing the Till ‘N Seed to trailers for transport. A seed calibration tray makes custom seed rate calibration easy is conveniently stored on the machine when not in use. Seed box disconnect pins disengage seeding mechanisms when the unit is used in tillage-only mode. |

|

THE DETAILS

The 8′ models are equipped with a small micro-metered seed box in front, a large micro-metered seed box in the middle, and an optional agitator seed box can be added on the rear. |

|

6′ MODELS

Three-Point Hitch: Cat. I, II, Quick-Attach and iMatch™ Compatible Hitch Can be Moved Off-Center for Use on Wider Tractors Drive and Tillage Rotors Made of Abrasion Resistant Steel Tillage Rotor Runs 2 1/2 Times Faster than Drive Rotor #80 Drive Chain Tillage Rotor Free to Follow Ground Contour Rotors Mesh Together for Self-Cleaning Design Air Shock Maintains Tillage Rotor’s Contact with the Soil Heavy-Duty 1 1/2″ Greaseable Bearings on All Rotor Shafts Adjustable Gauge Wheels Control Depth of Tillage Rotor Floating Cast Iron Firming Roller Provides Final Touch for Ideal Seedbed Double Seed Box Capacity Large Micro-Metered Seed Box for Planting Larger Seed Varieties Small Micro-Metered Seed Box for Seeding Smaller Seeds User Friendly Seed Rate Adjustments Three Seed Rate Ranges Available for Large Micro-Metered Seed Box by Changing Out Sprockets Seed Box Disconnect Klik Pin Disconnects the Seed Drive for Seed Rate Calibration and Prevents Wear and Tear on the Seed Box Drives in Tillage-Only Mode Wind Deflector Doubles as Trough for Catching Seed During Calibration Process Handrail, Step, and Walkboard Provide for Operator Safety Rubber Guard Prevents Debris or Residue from Being Projected from the Tillage Rotors Convenient Brackets Included for Securing Machine to Trailers and for Lifting Unit Integral Parking Stand Parking Pin Allows Unit to Maintain Correct Orientation When Unhitched from Tractor SMV Emblem Electronic Acre Meter Available Powder Coat Paint |

|

8′ MODELS

8′ Pull-Type and Three-Point Hitch Models Available Cat. II Drawbar on Pull-Type Models (2) 9.5L x 15-8 Ply Tires on Pull-Type Models Three-Point Hitch: Cat. II, III Free Link Three-Point Hitch: Cat. II, IIIN, III Quick Coupler Hitch Can be Moved Off-Center for Use on Wider Tractors on Three-Point Hitch Models Drive and Tillage Rotors Made of Abrasion Resistant Steel Tillage Rotor Runs 2.14 Times Faster than Drive Rotor #60-2 Drive Chain Tillage Rotor Free to Follow Ground Contour Rotors Mesh Together for Self-Cleaning Design Adjustable Air Shock Pressure for Varying Ground Conditions Heavy-Duty 1 1/2″ Sealed Bearings on All Rotor Shafts Adjustable Gauge Wheels Control Depth of Tillage Rotor Rubber Firming Roller Provides Final Touch for Ideal Seed to Soil Contact Small Micro-Metered Front Seed Box for Seeding Smaller Seeds Large Micro-Metered Second Seed Box for Planting Larger Seed Varieties Optional Third Seed Box: Blade Agitator for Seeding Larger Grass Seed Varieties User Friendly Seed Rate Adjustments Seed Box Disconnect Pins Disengage Seeding Mechanisms Slide-In Seed Calibration Tray Stores on Machine When Not in Use Handrail, Step, and Walkboard Provide for Operator Safety Convenient Brackets Included for Securing Machine to Trailers Integral Parking Stand Parking Pin Allows Unit to Maintain Correct Orientation When Unhitched from Tractor on Three-Point Hitch Models Electronic Acre Meter Available Optional Dual Wheel Kit Available for Pull-Type Models LED Safety Warning Lights & SMV Emblem Powder Coat Paint |

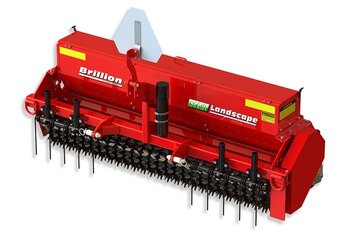

THE OVERSEEDER WITH THE CAN DO ATTITUDE

THE OVERSEEDER WITH THE CAN DO ATTITUDE

ONE AND DONE

ONE AND DONE