- Monday 8:00 AM - 5:00 PM

- Tuesday 8:00 AM - 5:00 PM

- Wednesday 8:00 AM - 5:00 PM

- Thursday 8:00 AM - 5:00 PM

- Friday 8:00 AM - 5:00 PM

- Saturday 8:00 AM - 12:00 PM

- Sunday Closed

Landoll B40I5 FORKLIFT

|

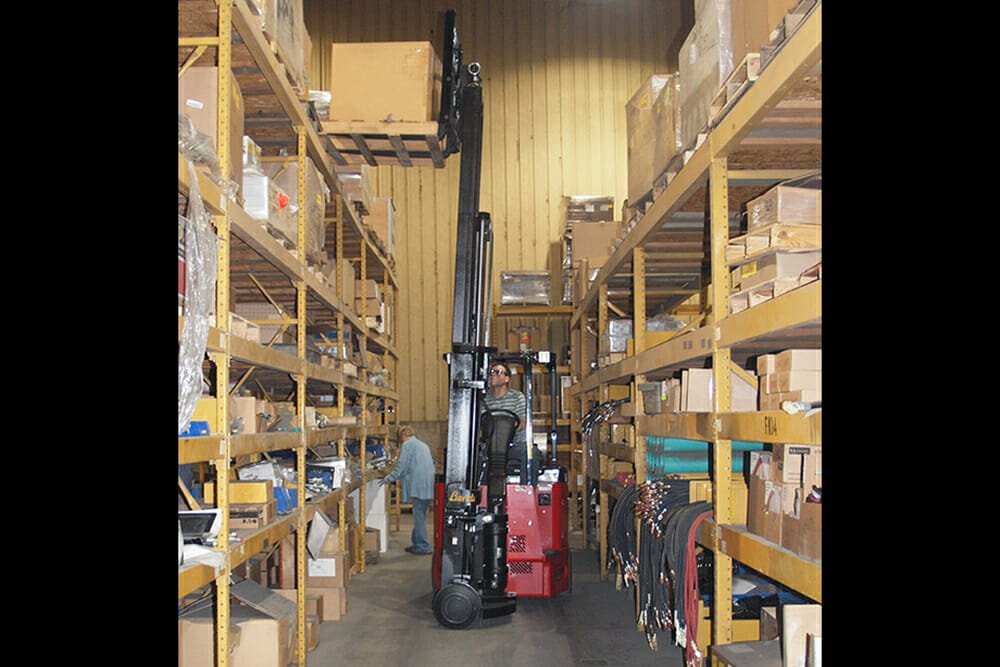

NARROW AISLE MULTIPURPOSE LP GAS FORKLIFT

It’s a 4-wheel articulating forklift with dual rear-drive tires and soft-poly front load tires. The hydrostatic drive provides excellent traction and braking, high-speed capability and power to enable climbing steep ramps with loads. Three or four stage masts are available making this unit excellent for loading/unloading trailers, containers and highway trailers. The Bendi B40i5 can work inside and outside on paved surfaces and has a floating front axle allowing the truck to ride smoothly over uneven floors. It can do the same jobs as reach and counterbalanced trucks but in much narrower aisles. |

EXCEPTIONAL PERFORMANCE AND MANEUVERABILITY

EXCEPTIONAL PERFORMANCE AND MANEUVERABILITY

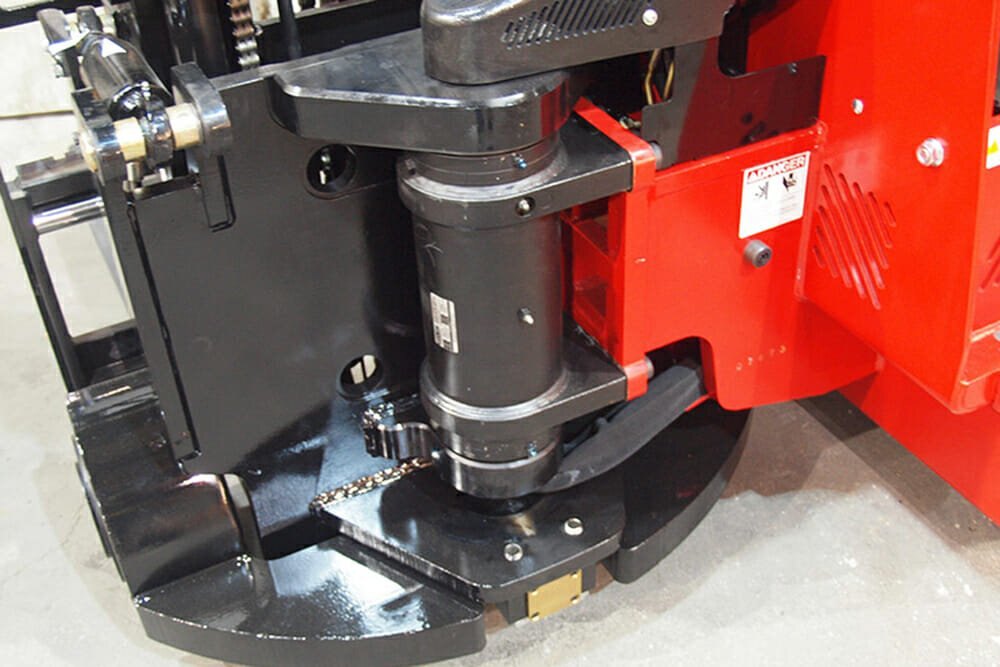

Equipped with the Landoll DuraSteerTM front wheel hydraulic steering, the B40i5 provides exceptional control and makes load placement and retrieval superior to the competition. |

MAXIMIZES MATERIAL HANDLING PRODUCTIVITY

MAXIMIZES MATERIAL HANDLING PRODUCTIVITY

The versatile Bendi B40i5 forklift replaces conventional reach and counterbalanced fork trucks in standard warehouse operations. The unique design allows operators to use it as a counterbalance truck indoors or out, yet operates in narrow aisles in your warehouse, replacing reach trucks that require much wider aisles. The Bendi B40i5 has large diameter tires and the truck has great under clearance for avoiding floor obstructions. One forklift can go from inside the truck to the rack eliminating staging and additional operators and support forklifts. |

| 4,000 lb. (1814kg) Capacity at 24″ (600mm) Load Center Four-Wheel Design, Dual Rear Wheel Drive Provides Excellent Power, Braking and Traction with Fast Travel Speeds Ergonomic Design for Exceptional Operator Comfort and Safety Integral Wide Stroke Side Shifter Makes Placing and Picking Loads Effortless DuraSteerTM Front Wheel Hydraulic Steering Provides Smooth, Reliable, Long-Lasting Steering Control Engine RPM is Controlled Automatically for all Hydraulic Functions without the Need for an Inching Pedal |

| High Visibility Mast Allows Optimum Safety and Control Hydrostatic Braking Assures Automatic Smooth and Safe Braking when the Operator Removes Foot from the Accelerator Pedal Integrated on Demand Tier III Fuel System Provides Efficient Control Over Engine RPM Ensuring Maximized Fuel Efficiency Dash Display with Hour Meter, Fuel Gauge and Engine Monitoring Via-Sonic Fuel Level Sensor with 99.5% Accuracy Simplified Maintenance, Diagnostics and Calibration Performed through the Dash Display |

| 4,000 lb. (1,814kg) Capacity at 24” (600mm) Load Center Tier III Certified, LP Gas, 2.5L, Kubota Industrial Engine Gear Driven Valve Train – No Belts or Chains CAN-Bus Electronics for Integrated Control of Drive, Lift and Steering Simplified Maintenance, Diagnostics and Calibration through Dash Display Dash Display with Hour Meter, Fuel Gauge and Engine Monitoring Via-Sonic Fuel Level Sensor with 99.5% Accuracy 180° Front-End “DuraSteer” Articulation / Steering Assembly with Extended Warranty |

| Heavy Duty Dual Rear Wheel Hydraulic Motors Automatic Hydrostatic Braking and Foot Activated Hydraulic Parking Brake Lift Heights to 360” (9.14M) 78” (1.98M) Stacking Aisle with 48” (1,219mm) Long Load High Visibility 3-Stage or 4-Stage Mast Integral 11.2” (285mm) Stroke Side Shifter and 36” (914mm) High Load Backrest Dual Indoor / Outdoor Capability Articulated 42” (1,067mm) Wide Floating Front Axle Large Diameter Smooth Rubber Drive Tires Polyurethane Load Tires |

| Comfortable Seated Operation with all Truck Controls within Easy Reach Adjustable Vinyl Suspension Swivel Seat Armrest and Adjustable Steering Column, Key Switch, Horn and Seat Belt Hydraulic Power Steering 4-Post Heavy-Duty Overhead Guard Safety Deadman Seat Switch Heavy Duty Unitized Robotic Welded Chassis Design Provisions for RF Terminals Provided Accepts Class II Attachments Easily Accessible Components for Low-Cost Maintenance |